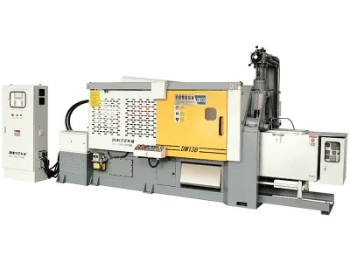

DM138T Reinforced Type Hot Chamber Machine

We supply 138Ton High Pressure Zinc Alloy Hot Chamber Die Casting Machine high precision with CE UL 2 years warranty.We devoted ourselves to die casting machine many years,covering Russia,India,South-east Asia and South-America markets.We are expecting become your long-term partner in China.

DM138T Zinc Alloy Hot Chamber Die Casting Machine

Die Platen Drawing & Parameter Table

Servo drive and single proportional control hydraulic power system

● Intelligent dynamic operation, high energy saving rate, clear high pressure throttling, reduce oil temperature.

● Servo drive has fast response speed.

● Single-proportional control of the hydraulic system, intelligent dynamic operation, clear high-pressure throttling, reduce oil temperature.

● Single-proportional control hydraulic system, pressure and speed can be adjusted.

● Improve the stability of the whole machine and ensure the product quality.

● Flexible and smooth action conversion, reduce the impact of action, and prolong the service life of machinery and molds.

Clamping system

● Four large bar guide pillars, using high-tensile steel as raw materials, the surface is hardened by high-frequency heat treatment, and the outer layer is re-plated with hard chrome, which has high wear resistance and prolongs the service life of the machinery.

● The three major formwork and machine hinges are made of high-strength ductile iron, and the five-point expansion structure of the toggle connecting rod provides strong clamping force.

● The clamping action is divided into multi-level pressure and speed control and low-pressure clamping protection function.

● The hydraulic ejection design of the cylinder provides balanced ejection force and reduces the factors of product ejection deformation.

● Adopt central electric lubrication system, advanced point-by-point quantitative lubrication. Ensure that the lubrication points near and far are evenly lubricated, and there are liquid level and pressure alarm functions to ensure the good lubrication effect of the machine.

● The machine is equipped with mold cooling water contacts, which is convenient for installation and operation.

Injection system

● An independent high-speed accumulator is adopted, which has sufficient storage capacity to ensure stable injection force.

● The slow injection speed can be controlled individually, with sensitive response and smooth action.

● The injection action is controlled by a certain speed, with a specific hydraulic system, which is suitable for various product process requirements with high surface requirements.

● Wide range of injection speed adjustment.

● The maximum air injection speed of high-speed injection is stable, which is the guarantee of producing high-quality castings.

● Low hydraulic impact, high repeatability, suitable for the production of high density castings.

● Piston energy storage structure improves action response, improves the integrity of the injection system, and reduces oil leakage points.

● Multi-injection position lifting, suitable for the production of molds with different structures.

Hydraulics

● Adopt fast differential regeneration clamping oil circuit system, the opening and clamping action runs smoothly and quickly, and improves production efficiency.

● Standard configuration of hydraulic core-pulling valve moving pattern plate 1 group.

● Use reliable brand hydraulic components (Tokyo, Yuken, etc.).

Electrical control systems

● In order to meet the needs of customers in different regions, there are different options for customers to choose from for the control system and touch screen: Siemens, Delta or Omron control system; Siemens, Delta, or WEINVIEW touch screens. Easy to operate, rich function pages, to meet the control of the die-casting process.

● Powerful parameter storage function, which is convenient for future production call, improves production efficiency, and maintains consistent product quality.

● The fuselage line is made of oil-resistant and temperature-resistant and covered steel wire protection wires, which are well protected even in harsh environments to ensure normal production.

● The unique position selection of rotary blanking hopper can be used by customers to choose a better blanking method according to the plant situation.

Product Applications

Air ejection system and spraying system(option)

We supply the air ejection from top side,to eject the parts fastly,to shorten the cycle time and improve the production.

The spraying system also aviable to supply.

Conveying system(option)

We can supply the special converying system,to keep the automatic production with lower cost,applied with more production requirement.

Intergrated Solution

Hot chamber die casting machine+Automation+Mould

DM Series:DM25-DM400