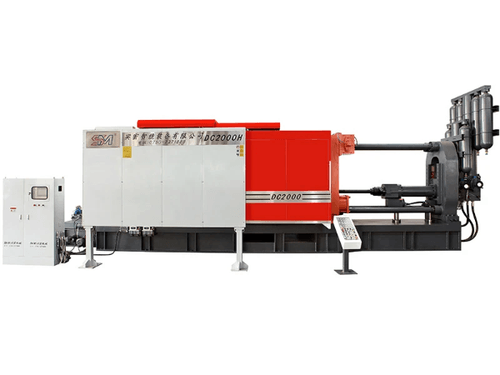

DC3000T Standard Cold Chamber Die Casting Machine

DC series cold chamber die casting machine,It is a new series developed in recent years, with higher cost performance.We supply 3000Ton Precision High Pressure Aluminum Alloy Cold Chamber Die Casting Machine with 2 years warranty.We devoted ourselves to die casting machine many years,covering Russia,India,South-east Asia and South-America markets.We are expecting become your long-term partner in China.

3000Ton Aluminum Alloy Cold Chamber Die Casting Machine

Clamping system

● Four large bar guide pillars, using high-tensile steel as raw materials, the surface is hardened by high-frequency heat treatment, and the outer layer is re-plated with hard chrome, which has high wear resistance and prolongs the service life of the machinery.

● The three major formwork and machine hinges are made of high-strength ductile iron and double-toggle connecting rod five-point expansion structure to provide strong clamping force.

● The clamping action is divided into multi-level pressure and speed control and low-pressure clamping protection function.

● Double-cylinder hydraulic ejection design provides balanced ejection force and reduces the factors of product ejection deformation.

● Adopt central electric lubrication system, advanced point-by-point quantitative lubrication. Ensure that the lubrication points near and far are evenly lubricated, and there are liquid level and pressure alarm functions to ensure the good lubrication effect of the machine.

● The fixed plate and moving plate are equipped with mold cooling water contacts, which are convenient for installation and operation.

Injection system

● Two independent high-speed and booster accumulators are adopted, each with sufficient storage capacity, and the high-speed and pressurization do not affect each other to ensure stable injection force.

● The slow injection is controlled by an electric proportional valve, which is sensitive and stable.

● The injection action is controlled by multi-stage speed, which is suitable for various mold product process requirements.

● Wide injection speed adjustment range, slow injection speed 0.1-1.4m/s.

● The maximum air injection speed of high-speed injection is ≧7m/s. Guarantee of high-quality castings.

● Active check pressurization system: short pressure construction time, small pressure impact, high repeatability. It is suitable for the production of high-density castings.

● Original active check pressurization system: short pressure construction time, small pressure impact, high repeatability. It is suitable for the production of high-density castings.

● Built-in pressurized piston structure improves action response, improves the integrity of the injection system, and reduces oil leakage points.

● Multi-injection position lifting, suitable for the production of molds with different structures.

Intergrated Solution

Cold chamber die casting machine+Automation+Mould