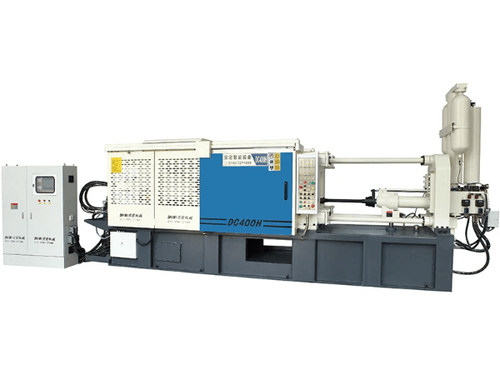

DC130 – DC3000 Servo energy-saving die-casting machine

Oil-cooled servo control energy-saving system

● The die-casting machine automatically adjusts the flow rate and pressure according to the computer setting, and the overall energy-saving effect can reach 45%~75%.

● Low noise, < 65dB during normal operation, to achieve quiet operation and improve the working environment.

● The dynamic response time of the whole system is < 50ms, and the production efficiency is increased by more than 5%~7% compared with ordinary models.

● The PID adjustment of the flow rate and pressure of the oil-cooled servo drive makes the repeatability of the entire oil circuit system controlled within 0.3% to ensure product quality.

● The double closed loop of flow and pressure is adopted to make the machine run smoothly and repeatedly, greatly reduce the impact, reduce the wear of each component, and prolong the service life.

Intergrated Solution

Cold chamber die casting machine+Automation+Mould